| Compressors and Refrigeration Circuits | |||||

|---|---|---|---|---|---|

❮

❯

This unit has (3) circuits wit (2) compressors per circuit for optimum redundancy and efficiency.

This unit has (3) circuits wit (2) compressors per circuit for optimum redundancy and efficiency.

1. Danfoss Variable Speed Scroll Compressors

w/ Easy Service Access

2. Convenience Outlet Power Transformer

3. Flex Conduit for all wiring

Pic1 - 80 ton Unit – Varispeed Compressors

1 / 4

This unit has (3) circuits wit (2) compressors per circuit for optimum redundancy and efficiency.

This unit has (3) circuits wit (2) compressors per circuit for optimum redundancy and efficiency. 1. Danfoss Variable Speed Scroll Compressors

w/ Easy Service Access

2. Convenience Outlet Power Transformer

3. Flex Conduit for all wiring

❮

❯

This picture shows a (2) circuit unit that does not have variable speed compressors that would be used in a traditional application where precision control is less important (ex.: outdoor make-up ventilation air to a building).

This picture shows a (2) circuit unit that does not have variable speed compressors that would be used in a traditional application where precision control is less important (ex.: outdoor make-up ventilation air to a building).

1. Single Speed Scroll Compressors

Pic8 - Standard Scroll Compressor

1 / 4

This picture shows a (2) circuit unit that does not have variable speed compressors that would be used in a traditional application where precision control is less important (ex.: outdoor make-up ventilation air to a building).

This picture shows a (2) circuit unit that does not have variable speed compressors that would be used in a traditional application where precision control is less important (ex.: outdoor make-up ventilation air to a building).1. Single Speed Scroll Compressors

❮

❯

Each independent circuit is provided with a refrigerant filter drier to keep each system clean. For this 80 ton unit there are 3 independent circuits.

Each independent circuit is provided with a refrigerant filter drier to keep each system clean. For this 80 ton unit there are 3 independent circuits.

1. Filter Driers Tagged per Circuit

Pic7 - Filter Driers

1 / 4

Each independent circuit is provided with a refrigerant filter drier to keep each system clean. For this 80 ton unit there are 3 independent circuits.

Each independent circuit is provided with a refrigerant filter drier to keep each system clean. For this 80 ton unit there are 3 independent circuits.1. Filter Driers Tagged per Circuit

❮

❯

All variable speed compressors are provided with oil level viewing ports to insure proper oil levels in the compressor. These ports provide easy inspection for the maintenance and service technicians.

All variable speed compressors are provided with oil level viewing ports to insure proper oil levels in the compressor. These ports provide easy inspection for the maintenance and service technicians.

1. Oil Level View Port Glass

Pic6 - Oil Level Glass

1 / 4

All variable speed compressors are provided with oil level viewing ports to insure proper oil levels in the compressor. These ports provide easy inspection for the maintenance and service technicians.

All variable speed compressors are provided with oil level viewing ports to insure proper oil levels in the compressor. These ports provide easy inspection for the maintenance and service technicians.1. Oil Level View Port Glass

❮

❯

Compressor are mounted on isolation rails with isolators reducing vibrations and provides noise reduction. The electrical power cables are installed in flexible conduit and then placed in an electrical cable for protection and neatness.

Compressor are mounted on isolation rails with isolators reducing vibrations and provides noise reduction. The electrical power cables are installed in flexible conduit and then placed in an electrical cable for protection and neatness.

1. Compressor Isolation Rails

2. Electrical Conduit and Cable Tray

Pic5 - Compressors

1 / 4

Compressor are mounted on isolation rails with isolators reducing vibrations and provides noise reduction. The electrical power cables are installed in flexible conduit and then placed in an electrical cable for protection and neatness.

Compressor are mounted on isolation rails with isolators reducing vibrations and provides noise reduction. The electrical power cables are installed in flexible conduit and then placed in an electrical cable for protection and neatness.1. Compressor Isolation Rails

2. Electrical Conduit and Cable Tray

❮

❯

Service ports and sight glasses allows for ease of servicing and trimming of the refrigerant charge. The sight glass insures proper liquid refrigerant and detection for water moisture.

Service ports and sight glasses allows for ease of servicing and trimming of the refrigerant charge. The sight glass insures proper liquid refrigerant and detection for water moisture.

1. Service Ports (3) Circuits

2. Sight Glasses for (3) Independent Circuits for this 80 ton unit

Pic4 - Service Ports & Sight Glass

1 / 4

Service ports and sight glasses allows for ease of servicing and trimming of the refrigerant charge. The sight glass insures proper liquid refrigerant and detection for water moisture.

Service ports and sight glasses allows for ease of servicing and trimming of the refrigerant charge. The sight glass insures proper liquid refrigerant and detection for water moisture.1. Service Ports (3) Circuits

2. Sight Glasses for (3) Independent Circuits for this 80 ton unit

❮

❯

The Electronic Expansion Valve (EEV) provides precise refrigerant flow to the DX coil and matches the variable speed compressor operation. This valve provides about 10,000 steps of capacity control for precise temperature control providing energy efficiency.

The Electronic Expansion Valve (EEV) provides precise refrigerant flow to the DX coil and matches the variable speed compressor operation. This valve provides about 10,000 steps of capacity control for precise temperature control providing energy efficiency.

1. Electronic Expansion Valve

Pic3 - EEV Valves

1 / 4

The Electronic Expansion Valve (EEV) provides precise refrigerant flow to the DX coil and matches the variable speed compressor operation. This valve provides about 10,000 steps of capacity control for precise temperature control providing energy efficiency.

The Electronic Expansion Valve (EEV) provides precise refrigerant flow to the DX coil and matches the variable speed compressor operation. This valve provides about 10,000 steps of capacity control for precise temperature control providing energy efficiency.1. Electronic Expansion Valve

❮

❯

Twin set of variable speed compressors with the full modulating Hot Gas Reheat Coil valve. This full modulating electronic valve provide precise

Discharge temperature control and FREE reheat to the air stream after during the dehumidification cycle.

Twin set of variable speed compressors with the full modulating Hot Gas Reheat Coil valve. This full modulating electronic valve provide precise

Discharge temperature control and FREE reheat to the air stream after during the dehumidification cycle.

1. Compressor Service Valves

2. Full modulating Hot Gas Reheat Coil Valve

Pic2 - Vari-speed Compressor

1 / 4

Twin set of variable speed compressors with the full modulating Hot Gas Reheat Coil valve. This full modulating electronic valve provide precise

Discharge temperature control and FREE reheat to the air stream after during the dehumidification cycle.

Twin set of variable speed compressors with the full modulating Hot Gas Reheat Coil valve. This full modulating electronic valve provide precise

Discharge temperature control and FREE reheat to the air stream after during the dehumidification cycle.

1. Compressor Service Valves

2. Full modulating Hot Gas Reheat Coil Valve

❮

❯

Refrigerant receivers for management of refrigerant during high and low capacity demands, reheat coils and heat pump duty units. Receivers are sized for the unit and application.

Refrigerant receivers for management of refrigerant during high and low capacity demands, reheat coils and heat pump duty units. Receivers are sized for the unit and application.

1. Refrigerant receivers

Pic9 - Recievers

1 / 4

Refrigerant receivers for management of refrigerant during high and low capacity demands, reheat coils and heat pump duty units. Receivers are sized for the unit and application.

Refrigerant receivers for management of refrigerant during high and low capacity demands, reheat coils and heat pump duty units. Receivers are sized for the unit and application.1. Refrigerant receivers

❮

❯

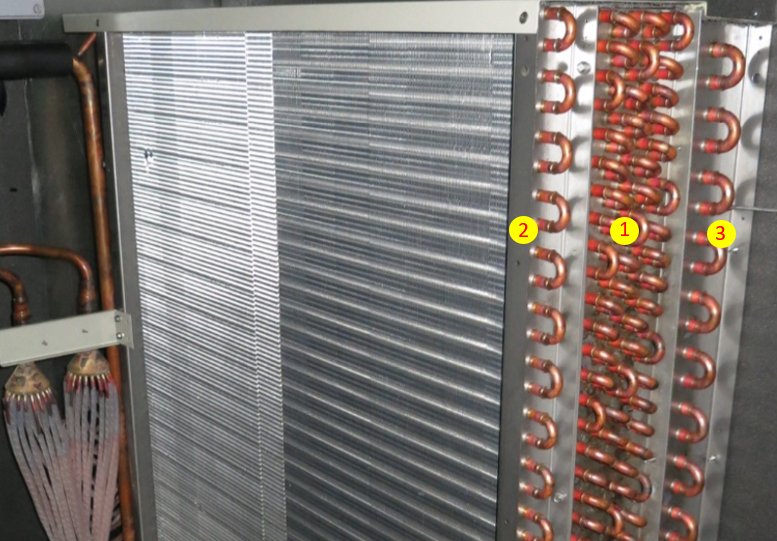

The units come standard with high capacity DX coils and Hot Gas Reheat coils. As, well, there are many other coil options that can be combined into the unit such as heating coils precooling coils and chilled water coils.

The units come standard with high capacity DX coils and Hot Gas Reheat coils. As, well, there are many other coil options that can be combined into the unit such as heating coils precooling coils and chilled water coils.

1. High Capacity DX Coil

2. Hot Gas Reheat Coil

3. Preheat Coil

DX Coils (pic10)

1 / 4

The units come standard with high capacity DX coils and Hot Gas Reheat coils. As, well, there are many other coil options that can be combined into the unit such as heating coils precooling coils and chilled water coils.

The units come standard with high capacity DX coils and Hot Gas Reheat coils. As, well, there are many other coil options that can be combined into the unit such as heating coils precooling coils and chilled water coils.1. High Capacity DX Coil

2. Hot Gas Reheat Coil

3. Preheat Coil

❮

❯

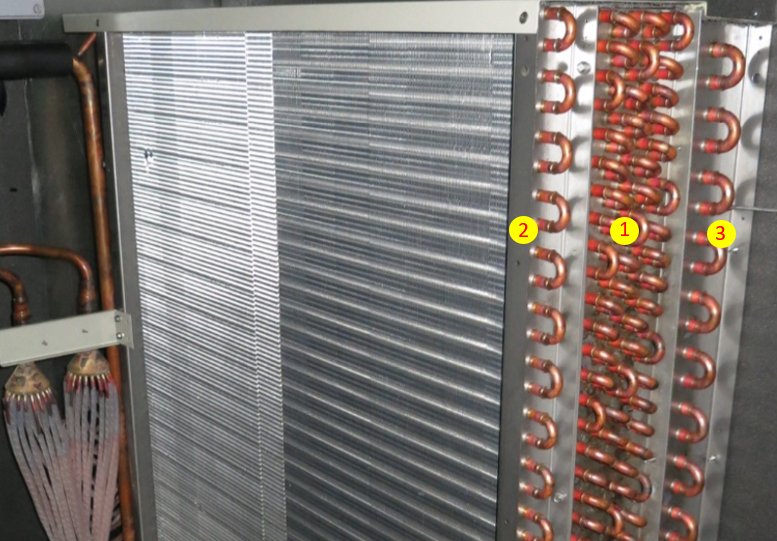

The many DX coil distributor tubes are wrapped with plastic to prevent tube wear and premature failure in the copper tubes.

The many DX coil distributor tubes are wrapped with plastic to prevent tube wear and premature failure in the copper tubes.

1. Distributor tube wraps

Ditributor Wraps (pic11)

1 / 4

The many DX coil distributor tubes are wrapped with plastic to prevent tube wear and premature failure in the copper tubes.

The many DX coil distributor tubes are wrapped with plastic to prevent tube wear and premature failure in the copper tubes.1. Distributor tube wraps

❮

❯

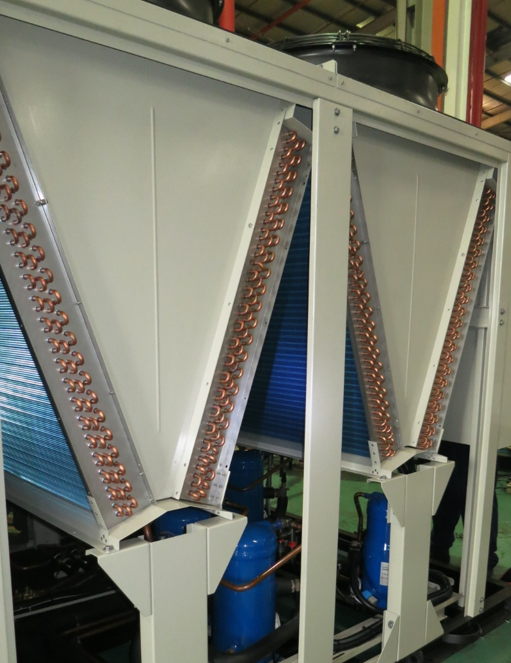

This unit utilizes an efficient V-bank condenser coil design reducing overall length and while improving surface area for efficiency. The unit may have one or more banks of coils

This unit utilizes an efficient V-bank condenser coil design reducing overall length and while improving surface area for efficiency. The unit may have one or more banks of coils

1. V-bank Condenser coil design.

Condenser Section (pic12)

1 / 4

This unit utilizes an efficient V-bank condenser coil design reducing overall length and while improving surface area for efficiency. The unit may have one or more banks of coils

This unit utilizes an efficient V-bank condenser coil design reducing overall length and while improving surface area for efficiency. The unit may have one or more banks of coils1. V-bank Condenser coil design.

❮

❯

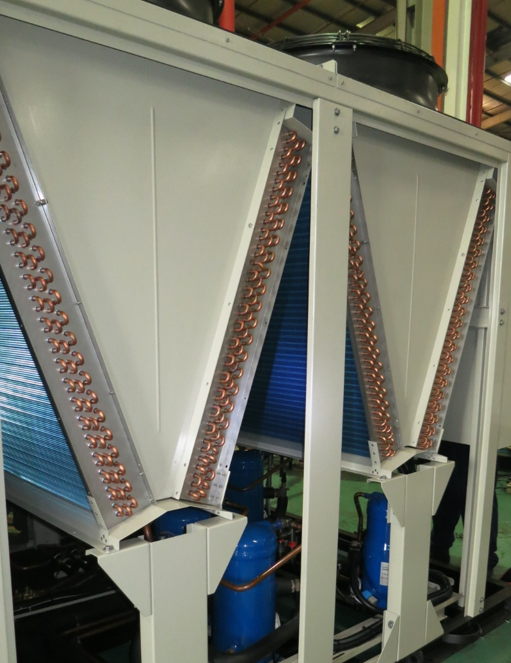

The unit has an independent frame for each condenser coil with precise refrigerant line knockouts with plastic sleeve inserts for tubing protections.

The unit has an independent frame for each condenser coil with precise refrigerant line knockouts with plastic sleeve inserts for tubing protections.

1. V-bank Condenser coil design.

2. Knockout sleeve protection

Vbak and Knockouts (pic13)

1 / 4

The unit has an independent frame for each condenser coil with precise refrigerant line knockouts with plastic sleeve inserts for tubing protections.

The unit has an independent frame for each condenser coil with precise refrigerant line knockouts with plastic sleeve inserts for tubing protections.1. V-bank Condenser coil design.

2. Knockout sleeve protection

❮

❯

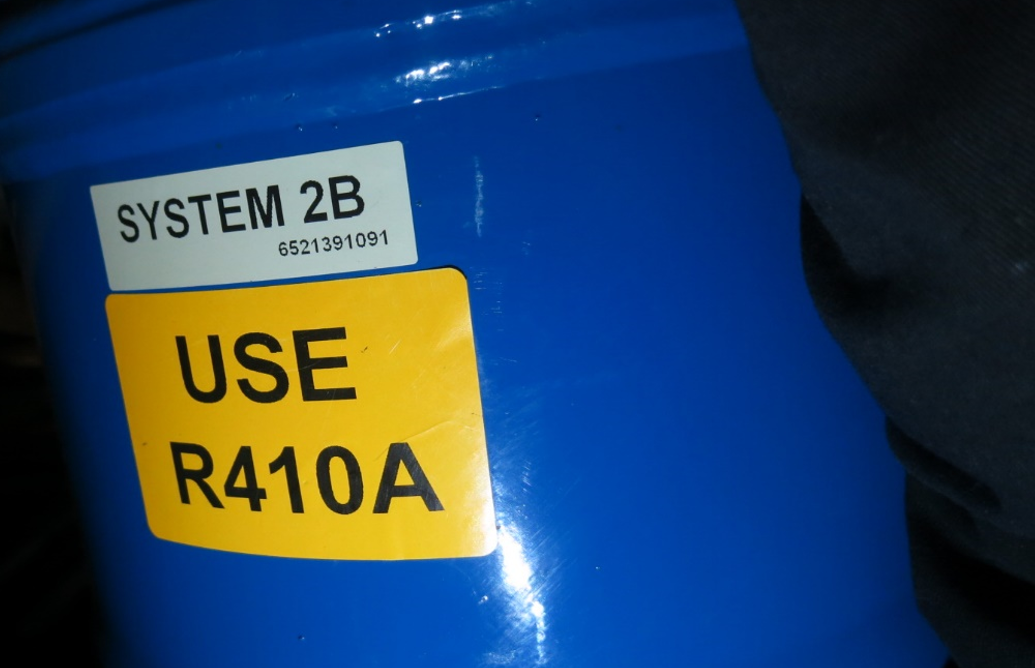

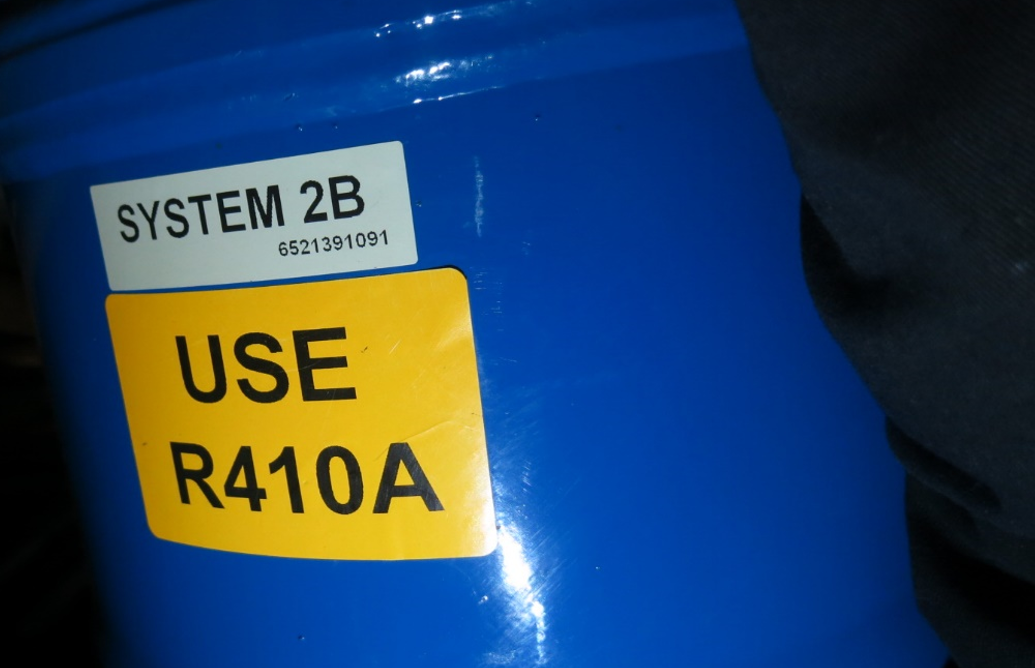

All units utilize Eco-friendly R410A refrigerant.

All units utilize Eco-friendly R410A refrigerant.

1. R410 A Refrigerant

Refrigerant R410A (pic15)

1 / 4

All units utilize Eco-friendly R410A refrigerant.

All units utilize Eco-friendly R410A refrigerant. 1. R410 A Refrigerant

❮

❯

Each circuit with a variable speed compressor must have a variable speed condenser fan to match the capacity and of the compressor. These fans will speed up and slow down to match this capacity and refrigerant pressures to optimize temperature control and efficiency. The vari-speed fans also provide low ambient control at no added charge.

The fan blades and shrouds are design for high efficiency and low noise.

Each circuit with a variable speed compressor must have a variable speed condenser fan to match the capacity and of the compressor. These fans will speed up and slow down to match this capacity and refrigerant pressures to optimize temperature control and efficiency. The vari-speed fans also provide low ambient control at no added charge.

The fan blades and shrouds are design for high efficiency and low noise.

1. High Efficiency,

2. Low noise

3. Variable speed condenser fans.

Condenser Fans (pic14)

1 / 4

Each circuit with a variable speed compressor must have a variable speed condenser fan to match the capacity and of the compressor. These fans will speed up and slow down to match this capacity and refrigerant pressures to optimize temperature control and efficiency. The vari-speed fans also provide low ambient control at no added charge.

The fan blades and shrouds are design for high efficiency and low noise.

Each circuit with a variable speed compressor must have a variable speed condenser fan to match the capacity and of the compressor. These fans will speed up and slow down to match this capacity and refrigerant pressures to optimize temperature control and efficiency. The vari-speed fans also provide low ambient control at no added charge.

The fan blades and shrouds are design for high efficiency and low noise.

1. High Efficiency,

2. Low noise

3. Variable speed condenser fans.

Categories

- Cabinet Features (9)

- Compressors and Refrigeration Circuits (17)

- Controls and Power Section (4)

- Fan Options (0)

- Filters Options (9)

- Coils (0)

- Outside air Dampers and Hoods (7)

- Supply and Exhaust Fan Options (0)

- Air Discharge Opening Options (0)

Unit are provided with durable polymer handles and clasps and are provided with a locking door latch for safety and security.

Unit are provided with durable polymer handles and clasps and are provided with a locking door latch for safety and security. Easy access to the washable aluminum mesh filters. These prefilters are provided to remove larger airborne debris and to provide protection against bugs and insects.

Easy access to the washable aluminum mesh filters. These prefilters are provided to remove larger airborne debris and to provide protection against bugs and insects.